Elevator Conveyor Belting

Elevator conveyor belts:

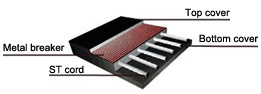

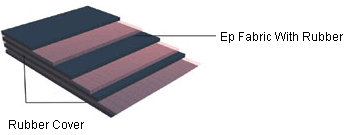

The belt is made of either anti-tearing EP canvas or steel cord as center material with anti-tearing rubber cover, good application capability, running steadily, low maintenance.

Construction:

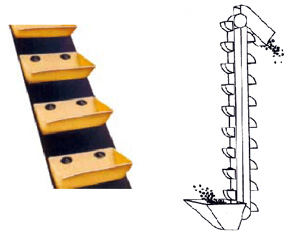

Rubber belt & elevator bucket.

Characteristics:

Little earth coverage, no pollution, great conveying capacity, suitable for conveying bulk material.

Application:

Vertical transportation of loose powdery material, widely used in building, mining, chemical, light industry, power station and grain etc. field.

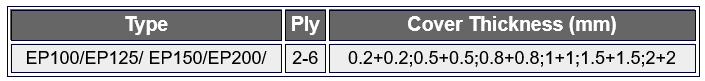

Standard Specifications of the rubber belt:

Carcass: EP or Cotton Duck

Max. Belt Width: ~2200 mm

Cover Rubber: Resistant to wear, oil, heat and anti-static.

Elevator Buckets:

Standard offers the most complete range in plastic elevator buckets. All types are available in HDPE or Nylon. Special buckets for minerals in extra heavy duties, centrifugal or gravity discharging.

Deep Bottom Bucket

Shallow Bottom Bucket

Bottomless Bucket

Split Bucket

Rice Milling Bucket

European Style Bucket

Inductive Bucket

Elevator Bucket Bolts:

Elevator buckets are fitted to belts by means of specially designed bolts. The type of bolt used depends on the design of the back wall of the bucket and the shape of the holes in the bucket.